Ever wonder how oil is produced from the ground? Notice the drilling down deep into the earth. Drills are used to make holes, so that oil comes up with gravity on the top of it and then this can be collected. This essential work is performed by oil companies using unique tools called drill bits developed in multiple sizes and forms fitting multitude of drilling purposes.

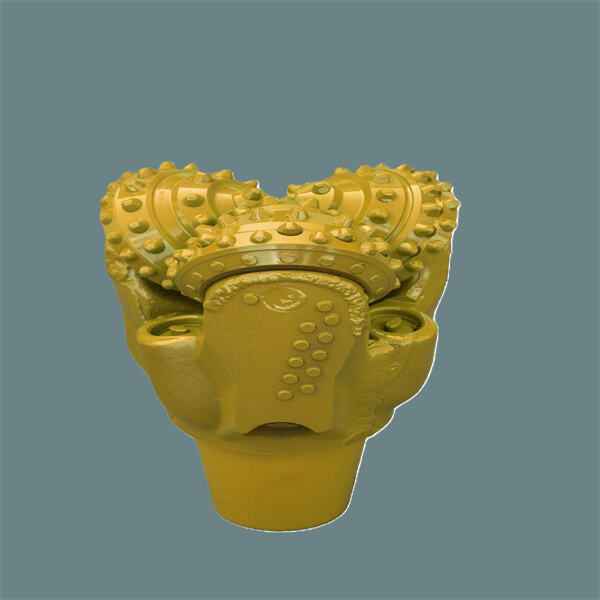

There are three types of main oil drill bit in commonly used such as tricone bit, PDC bit and diamond bit. Tricone bits are dependent on three cones spinning concurrently to grind down the rock and bore a hole. This bit works well on many different types of rocks. DeepFast drill bit petroleum have lots of small diamonds stuck to their core. These diamonds have a knife-edge sharpness that can cut the rock away. This type of bit has a solid diamond surface that makes it very easy to grind through even the densest rock.

Tricone bits are ideal to go through sandstone and clay-based rocks. They are also strong, but maybe not always the fastest. PDC bits are ideal for drilling granites, shales and other hard formations because they drill faster than roller cone bits. DeepFast diamond core drill bit for oil and gas is the only option when it comes to cutting through something as hard as diamonds - and that includes olivine.

All drill bits come with their own unique set of pros and cons. An excellent example is tricone bits which are extremely consistently in a variety of drilling environments. Their PDC bits are typically fast and highly efficient, which could lead to considerable time and money savings. Tre generally more expensive and can break easily if not used cautiously. Diamond bits are great investment since they last such a long amount of time but can be expensive for some companies to purchase.

Drillers strive constantly to drill better for less. They also want to do it better and faster than ever, which has led the way for new developments in drill bit technology. One of the most exciting new types is called direct action bits. Water flows at high pressure in these DeepFast downhole tools oil and gas, which come with a unique hydraulic system for a powerful jet that carved through rock as if it were laser. This makes the bit last longer and helps to drill more quickly.

Another smart type is a new product called "smart" bits. These bits include sensors in them. This would allow the technology to keep an eye on how drilling is progressing, in real time. The down hole tools oil and gas can also automatically alter the velocity and force of drilling glass so that it is always functioning at full functionality. This ensures that oil companies extract the optimal amount of value from their drilling operations.

Aside from having to select the appropriate kind of drill bit, oil businesses may use particular bits that matches their prerequisites and enhance its efficiency. Reamer bits are used to enlarge a hole after it has been drilled. The fact that more oil is able to flow through said. This widening increases the amount of spilled oil collected tweaking overall amounts dramatically. Another type of specialty bit is a "coring" bit. These downhole equipment oil and gas are used to create a cylindrical core sample of the rock. The resulting sample can then be processed in a lab setting to learn more about the geological characteristics of the area.

Design manufacture downhole tools for the companies the oil and gas industry across globe. Deep Fast deploys professional equipment and technical teams to service the oil and gas industry seeking safe, efficient and secure solutions. Rapid response quick responses to the client's needs concerns. Positive Displacement Motor (PDM) is able to adapt to various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Petroleum drill bits types, they manufacture Short Bit to Bent PDM In addition, PDM for Coiled Cubing is available. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, and more. are available. Drill Bits are offered in various sizes and are able to be customized to meet the requirements of our clients.

Deep Fast Oil Drilling Tools., Ltd. can offer all options customers. From initial inquiry to the creation of the product from manufacturing to delivery, Deep Fast has a complete management system. Deep Fast offers downhole tools customers North America, South America and Russia. They also provide pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast will also modify the product meet the needs of the Petroleum drill bits types in accordance with the particular situations that they are facing. Deafest has always stuck to the principles of "Constancy Integrity, Determination Success" as well as the objective of "Starting with the need for drilling and finishing with satisfaction from our clients".

Deep Fast developed an Integrated Management System that follows guidelines of API Spec Q1 ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health Safety), ISO 14001:2015 (Environmental). Deep fast will test all products starting from raw materials final product. reports these tests will be sent to customers. Deep Fast has a system of management that protects our employees our Petroleum drill bits types. Every procedure manufacturing product will adhere to these standards.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 has more than 35 years of experience with downhole tools. Located Chengdu, China, Deep Fast provides PDC Bits in different sizes, Downhole Motor used different operation situation, complete spare parts support the products. Install Japan 5-axis NCPC and Germany Modern lathe, Deep Fast produces annually an average of 8000 diamond bits, 2000 downhole motors. Work with Petroleum drill bits types Petroleum University for a longer-term plan, so far, 50 patents that includes 2 American patents,2 Russian patents, 46 Chinese patents have been granted.