We all think about cars and all those fuels which help our vehicles to run, i.e oil. The oil however, is a lot more than just something that gets our cars running! Do you realize that oil can be converted into materials we use for many different purposes in life? For instance, oil is used to produce the plastic things we use like make up on our skin or along with crayons that children use for drawing and coloring. In order to extract the oil from beneath our feet, we have a special way called "oil drilling," which is actually nothing more than using some tool and methods.

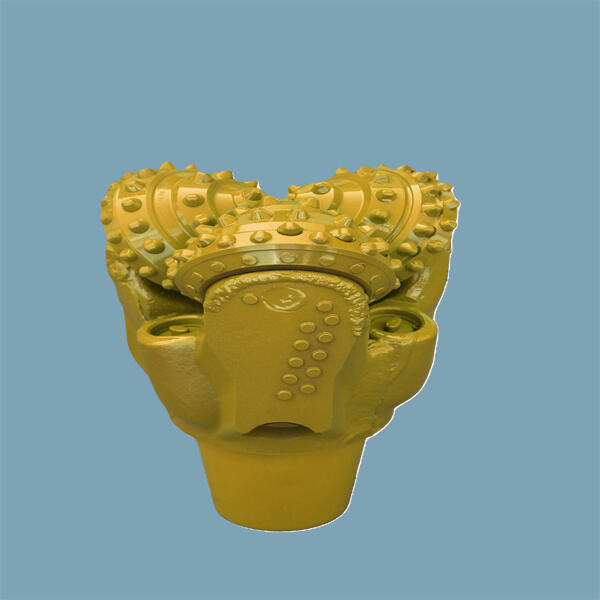

Oil drilling involves excavating the ground in order to find oil buried under it. The process is hard and needs special machines, tools and skilled workers to work them. The DeepFast diamond point tricone bit is arguably the most important component when it comes to drilling, as it enables quicker and more effective oil drilling operations.

Oil drilling used to be a slow and difficult process before the invention of the tri cone bit. People resorted to breaking through tough rocks and soil using traditional tools such as chisels and hammers. That is what slow and cumbersome the process was. A man named Howard Hughes Sr. however effectively changed this standard in the early 1900s that saved countless lives.

Hughes was a shrewd inventor and businessman looking to improve the oil drilling bit. The bitstyle he developed (the tri-cone in which three cones with teeth rotated independently) has since become known as a "roller cone. Conventional tools could hardly keep up with the pace of a hole being driven at breakneck speeds through rocks and hard ground by these rapidly-rotating cones. The oil-drilling process changed by this invention and it brought a huge time-saving reality to workers.

A tri cone bit has three cones, and each of these cones contains its own set of teeth. These DeepFast cone drill bit are attached to a central shaft that runs all the way up into what is called a drilling machine or, more appropriately,would be referred as drill rigs. As the drilling machine starts, these cones start rotating in opposite directions. This rotation helps to dislodge the rock and soil, thereby opening a path for oil to come in direct contact with incoming water.

But again, there are downsides. Because of their high production costs, tri cone bits may not be suitable for smaller drillings that cannot afford the proper maintenance they need. Moreover, The tri cone bits need professional workers to operate as they are not user-friendly. Without the knowledge of how to achieve that, it may be difficult to obtain the resources.

Tri cone bit technology has been improved dramatically over the years. They have come up with new materials and designs that make them even stronger, more efficient. To this day, DeepFast bit tricone are still considered one of the most crucial tools used in oil drilling and also act as a very important means to extract more oils from yesterday where it would not have been possible.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. offers a complete process management system. From inquiry to design product, production, delivery, Deep Fast can provide all service to customers. Deep Fast offers downhole tools as well related services customers from North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Furthermore, Deep Fast can customize products its customers based on the different situations in operation Tri cone bit the challenges that customers encounter. Deafest has always adhered to the value of "Constancy Discipline, Integrity, Diligence and Achievement", the mission of "Starting at the beginning of drilling needs and finishing with satisfaction from customers".

Design manufactures downhole equipment for industries oil and gas around world. DeepFast offers professional equipment teams technicians to oil and gas companies looking for high-quality, safe and reliable solutions. Quickly responsive receptive clients' questions and requests. Positive Tri cone bit motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) or Vertical Drilling Systems (VDT). PDMs also available for Coiled Cubing as well as Short Bit to Bend PDM are also available. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc. Drill Bits are available in a variety size and are able to be customized to meet the requirements of our clients.

Deep Fast has developed an Integrated Management System follows the guidelines of API Spec Q ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health and Safety), ISO 14001:2015 (Environmental). From raw materials through to products, deep fast will take Tri cone bit test measures ensure the high-quality products. the results tests will be available to the customers. Also, in relation to HSE, Deep Fast have the safety system place protect our employees, as well as safeguard environment, every procedure for manufacturing product is governed by these guidelines Each month, the company will conduct the safety meeting and training internal, some personnel in the key positions will be enrolled in professional training outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. was founded in 2008 and has over 35 years' experience downhole tools, located in Chengdu, China, Deep Fast can provide PDC Bits different dimensions, Downhole Motor used various operating conditions, complete spare Tri cone bit the tools. Deploy Japan 5-axis NCPC Germany Modern lathes, DeepFast manufactures annually 8000 diamond bits and 2000 downhole motor. Southwest Petroleum University has been cooperating with us several years. In the past, 50 patents have been received with 2 of them being American patents and two Russian patents.