Having the correct tools is an crucial part in oil or gas. We utilize a tool called the DeepFast Tricone rock bit, which is one of our most crucial tools. This tool contains three cones which comes with strong teeth that allow us to penetrate even into the hardest rock or other hard materials. Here is what we are going to cover: How Tricone Rock Bits Works Why We Use These in Drilling

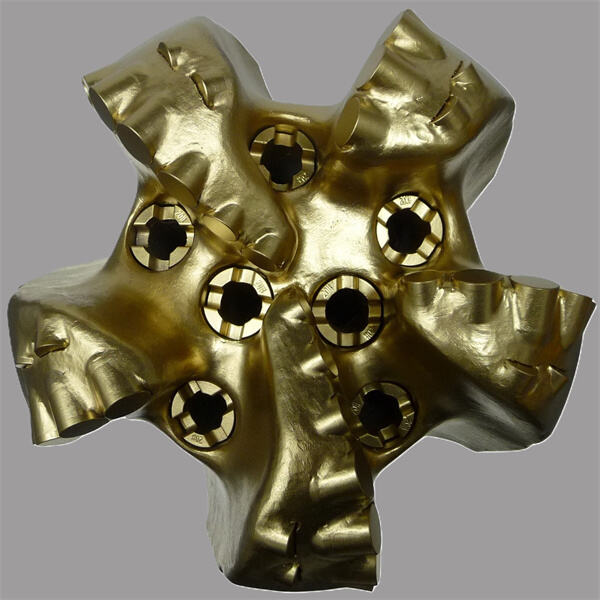

Diomand core bit: Tricone rock bits are unlike other types of drilling tools in that they have three cones instead of one. The numerous, sharp teeth of each cone bear against the blocks when we drill. As the bit rotates, so to do some partials, milling in a crushing action on breaking apart rocks and other compounds. Tricone rock bits are capable of making quick work within some really tough surfaces with the main reason behind this being its unique design

One of the top things about DeepFast Tricone rock bits is that they can be used in a very wide range. So they can be used in a wide variety of drilling jobs like drilling shallow wells, deep wells for water or paraphrasing mining minerals and even construction based projects. Tricone rock bits are one of the most versatile types of drill heads, making it a popular choice across many industries.

Diamond pdc drill bit are also known for having an exceptional service life. This allows them to last longer so that they can be used for various drilling applications without the frequent need for being changed. They are built tough to withstand the high pressure and temperatures encountered while drilling deeply into the Earth. This strength and durability make Tricone rock bits an efficient option for several drilling applications, as they can save time and money

The other great thing about DeepFast Tricone rock bits is that they be designed to excel in specific types of the rocks. By utilizing the correct diamond tip drill bit, a drilling company can benefit from seeing an improved performance and having better results on their projects. This is because certain types of rock have an impact on which tools will effectively break through the materials, and a proper bit can be everything when it comes to drilling

DeepFast Tricone rock bits are constantly updated to comply with the requirement of drilling job. Some newer, more effective designs are in the process of being put together to break through hard rock layers. Some newer diamond point Tricone bit have teeth that are tipped with diamonds, allowing them to last even longer than they already do. But certain blocks of ones (like those suited for frequency or rock such as shale or sandstone that are difficult to drill through) are designed in an optimum configuration

The solution has been the use of DeepFast Tricone rock bits, a type that first saw widespread usage more than a hundred years ago and which remains an essential part of oil & gas drilling to this day. Directional drilling mud motor would be far more difficult, and therefore expensive, without these amazing tools. With their versatile skillsets, immense strength and world-class equipment these drilling companies can now bore deeper into the earth at a faster rate than ever before to help support global energy demands

Deep Fast's Integrated Management System based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). Deep fast will test all its products from materials through final products. reports of tests will be made available customers. After that, will inform customers about HSE, Deep Fast have the management system that protects the employees of our company, and protect the environment, every procedure manufacturing product Tricone rock bit by these guidelines every month hold the safety meeting as well as training internally, some employee's key positions will take part in training professionals outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 with over 35 years' experience with downhole tools. Based in Chengdu, China, Deep Fast can provide PDC Bits different sizes, Downhole Motor used Tricone rock bit operational situations, spare parts needed maintain products. Deep Fast makes use of Germany modern lathes well as Japan 5-axis NCPC manufacture annual output 8000 diamond pieces. Collaborate with Southwest Petroleum University a long-term plan. As of now, 50 patents including 2 American patents,2 Russian patents, 46 Chinese patents have been obtained.

Create manufacture downhole tools to serve the oil gas industries across the globe. Deep Fast provides professional equipment and technicians to companies in the oil and gas industry looking for safe, efficient and reliable solutions. Rapid response and responsiveness client's questions and requests. Positive Displacement Motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) Tricone rock bit Drilling System (VDT). Also manufacture the Short Bit to Bent PDM, additionally, PDM for Coiled Cubing is provided. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc,. Drill Bits available in a variety of sizes and are able be designed meet the requirements of our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. offers a complete process management system. From inquiry to design product, production, delivery, Deep Fast can provide all service to customers. Deep Fast offers downhole tools as well related services customers from North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Furthermore, Deep Fast can customize products its customers based on the different situations in operation Tricone rock bit the challenges that customers encounter. Deafest has always adhered to the value of "Constancy Discipline, Integrity, Diligence and Achievement", the mission of "Starting at the beginning of drilling needs and finishing with satisfaction from customers".