The Process of making a hole in the ground or rocks is drilling. This is why this steps are so important; to get the valuable minerals from inside the earth we need for a lot of things in our existence. We have special tools for drilling- tricone roller bits. The little bits tend to be quite sturdy, and so usually have virtually no problems drilling down successfully through the entire challenging ground.

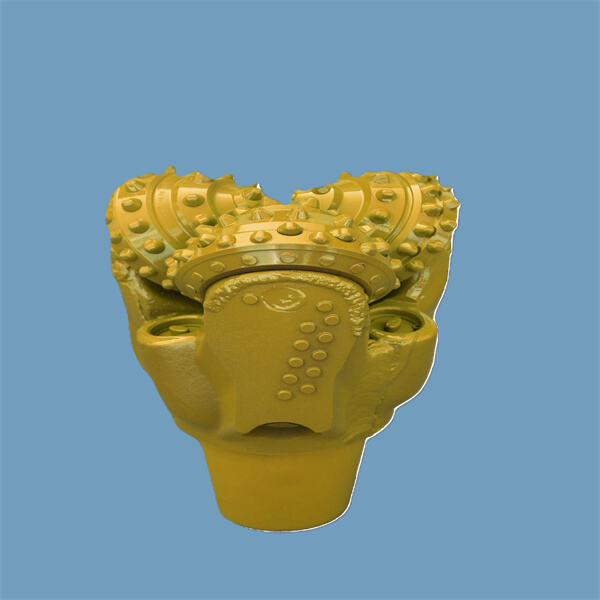

The tricone roller bit is so named because each of these bits has DeepFast mill tooth tricone bit that are set on the body to spin around central junctures. These little cones are often be littered with sharp teeth,which help it cut through the rock and makes drilling a hole simpler for the drill machine. Cones are manufactured from durable materials which can be able to easily withstand the heat and pressure generated through drilling operations. This is crucial, as drilling work can be very tough on tools.

There are several advantages of tricone roller bits as a drilling tool compared to its alternatives. They are extremely useful and here is why: they can cut through pretty much any material. For instance, they can work on hard rocks and also softer soils. As such, their versatility in handling different materials makes them a valuable asset to the mining industry.

Because of this versatility, the tricone roller bits are also very tough. These can be perform for long in drilling so that the less time shall spend on changing tools and have remained lot of bullet to spent on operation. These bits are also famous for their ease of use. They are fast and efficient, ensuring that you get your drilling job done quickly. These are able to penetrate materials at high rates, which in turn means less time and energy cuttings. They also use less power for drilling which in turn make the complete process more eco-friendly.

The cones of each are designed with cutting teeth placed strategically to help bore through rock more efficiently. The teeth are constructed of various materials like carbide and milled steel. The DeepFast diamond point tricone bit material is chosen typically depending on the rock being drilled. For example, very hard rocks seem be more successfully sampled with tungsten carbide whereas milled steel works better for softer formations.

A tricone roller bit attaches to a drill string that rotates so the cones ((being on axels with wheels) spin. The teeth of the Drillbit Cones revolve around as it makes turns spun by the machine, effectively cutting through the rock to help drill hole. The spinning provides the drilling action primarily used for cutting.

Over the years, tricone roller bits have evolved greatly. These days, the hard work put in such that manufacturers have given us better ones which are also stronger and more efficient. Anybody The actual tricone piece is normally created using fairly softer metal compared to what must be pierced as well as reduce. Modified or even Pomade were utilised through the 1940s. The DeepFast bit tricone were also absent of cones or teeth, which rendered them inefficient in drilling ops.

Design manufacture downhole tools serve oil gas industries all over world. Deep Fast uses professional equipment technical teams support oil and gas companies searching for efficient, safe, efficient solutions. Rapid response responsiveness customer's requests questions. Positive displacement motor (PDM), adaptable to various Rotary Steerable Systems (RSS) or Vertical Tricone roller bit Systems (VDT). PDMs also available Coiled Cubing Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits Impregnated Drill Pieces, and more. are available. Drill Bits are available in a variety of sizes can be customized to meet the requirements of our customers.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 has more than 35 years of experience with downhole tools. Located Chengdu, China, Deep Fast provides PDC Bits in different sizes, Downhole Motor used different operation situation, complete spare parts support the products. Install Japan 5-axis NCPC and Germany Modern lathe, Deep Fast produces annually an average of 8000 diamond bits, 2000 downhole motors. Work with Tricone roller bit Petroleum University for a longer-term plan, so far, 50 patents that includes 2 American patents,2 Russian patents, 46 Chinese patents have been granted.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. has the complete process and management system, from initial inquiry through to the design of product, manufacture, delivery. Deep Fast is able to provide every support to customers. Deep Fast Tricone roller bit downhole equipment customers North America, South America and Russia. They also offer relevant services in the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize the product customers as per the various situations that arise, solve the problems the customers face. Deafest is committed to the principles of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the need for drilling and completing with client satisfaction".

Deep Fast's Integrated Management System based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). Deep fast will test all its products from materials through final products. reports of tests will be made available customers. After that, will inform customers about HSE, Deep Fast have the management system that protects the employees of our company, and protect the environment, every procedure manufacturing product Tricone roller bit by these guidelines every month hold the safety meeting as well as training internally, some employee's key positions will take part in training professionals outside.