Do you know oil is an integral part of our daily lives? We make automobiles, electricity and even plastics are products of oil, similar to the DeepFast's product like core drill for steel. Oil is used to power our vehicles, heating in homes and producing everyday products. Extracting oil from deep underground, however, is more involved than simply punching a hole in the ground. These drilling bits are specialized for constructing an oil well. The purpose of these tools is to help us get at the oil caught within the rocks beneath our feet. This article examines the various types of drill bits employed in oil wells and how they are used.

Core Bits: Tools used to extract samples of the rock in the ground. These samples are crucial in aiding the work of scientists who study rock type and assess whether or not it may contain oil. When we examine these samples, it opens up a lot of secrets that lie beneath the skin.

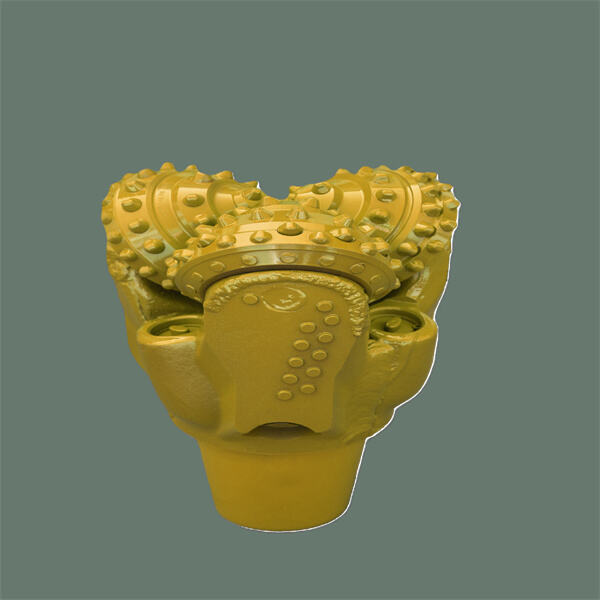

This type of bit is called a roller cone bits, because there are three cones that roll against the rock drilling and as they do create the wellbore. The cones spin and cut through the rock as they turn, allowing the oil to be more easily reached. This type of was is powerful and used in variety drilling operations.

PDC bits: PDC - Polycrystalline Diamond Compact are a new type of drill bit with a matrix body as well but it has certain advantages over Tricone bits, just like the High Output Torque created by DeepFast. Instead of the anterior head covered by lots teeth these ones intended to be that one large diamond covering entire face. The diamonds assist the bit in grinding into the rock better than any others. Thus, PDC bits are very high-performance pieces of drilling kit.

The most critically important part of the drilling process is choosing a proper bit, along with DeepFast's product Bit design. It will depend upon the rock type as well how deep is your water bearing formation. For instance, if the well is not deep and rock formations are soft then milling tooth bit would less costly to use. If it is, however a tougher rock then go with the TCI or PDC drill bit as they are made to deal with much harder materials.

In the field a device known as core bits are used to extract rock samples, as well as the mud motor oilfield created by DeepFast. The bit drills into the ground, and this creates a cylindrical section of rock removed. then removed from the hole, and analyzed to ascertain if there has any oil in it. It is a necessary process for studying the geology of this region.

Raised cone bits are made up of three inner cones with sharpened teeth that spin when the bit is turned, the same as DeepFast's pdc cutter. They work by making the cones rotate, grinding against the rock and boring a hole. However, the cones might be made from various materials like tungsten carbide or steel according to drill different type of rock.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. founded in 2008, with more than 35 years' experience downhole tools, located Chengdu, China, Deep Fast can provide PDC Bits various sizes, Downhole Motor used different operation situation, complete Types of drilling bits for oil wells parts can be used support equipment. Deep Fast uses Germany modern lathe and Japan 5-axis NCPC to make 8000 diamond bits each year. Collaborate with Southwest Petroleum University for long-term plan. As now, 50 patents including 2 American patents, 2 Russian patents, 46 Chinese patents were obtained.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. offers a complete process management system. From inquiry to design product, production, delivery, Deep Fast can provide all service to customers. Deep Fast offers downhole tools as well related services customers from North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Furthermore, Deep Fast can customize products its customers based on the different situations in operation Types of drilling bits for oil wells the challenges that customers encounter. Deafest has always adhered to the value of "Constancy Discipline, Integrity, Diligence and Achievement", the mission of "Starting at the beginning of drilling needs and finishing with satisfaction from customers".

Deep Fast has developed an Integrated Management System follows the guidelines of API Spec Q ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health and Safety), ISO 14001:2015 (Environmental). From raw materials through to products, deep fast will take Types of drilling bits for oil wells test measures ensure the high-quality products. the results tests will be available to the customers. Also, in relation to HSE, Deep Fast have the safety system place protect our employees, as well as safeguard environment, every procedure for manufacturing product is governed by these guidelines Each month, the company will conduct the safety meeting and training internal, some personnel in the key positions will be enrolled in professional training outside.

Design manufacture downhole tools for the companies the oil and gas industry across globe. Deep Fast deploys professional equipment and technical teams to service the oil and gas industry seeking safe, efficient and secure solutions. Rapid response quick responses to the client's needs concerns. Positive Displacement Motor (PDM) is able to adapt to various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Types of drilling bits for oil wells, they manufacture Short Bit to Bent PDM In addition, PDM for Coiled Cubing is available. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, and more. are available. Drill Bits are offered in various sizes and are able to be customized to meet the requirements of our clients.