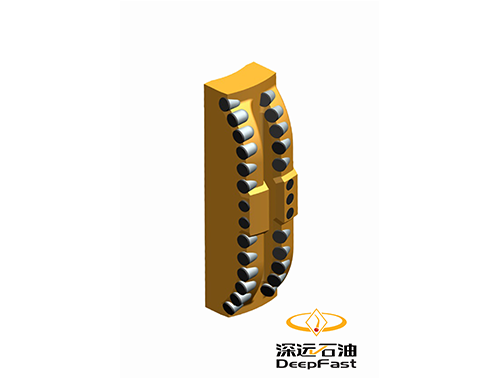

Top 5 Manufacturers to Help You Find a Downhole Drilling Motor in BrazilWhether you are drilling deep into the earth for oil or water, a durable and strong down hole drilling motor can contribute significantly to your success. In the land of natural resources, Brazil faces a significant quandary - locating the perfect downhole drilling motor is crucial with industries across oil & gas extraction and mining to geothermal energy. There are a million options out there, who can decide the best one. Most of information that you can use were taken from manufacturer's website, being this text the most complete source to help make at your next acquisition decision: Which are top 5 downhole drilling motor manufacturers in Brazil? Benefits of Downhole Drilling MotorDownhole drilling motor is a rotating drill tool that turns the drill bit and transmits the torque and power from surface to bottom hole. Key Advantages of Downhole Drilling Motors over other forms of drilling mechanisms like top-drive drilling or cable tool drilling include:- High speed and high torque capacities to drill in hard, abrasive formations- Flexible design that allows the motor bend directions for conventional horizontal or deviated wells and improved accuracy with increased control- Lowers vibrations during string formation as well as improves overall efficiency.- Adaptable to different types of parameters such weight on bit (WOB), flow rate and mud propertiesInnovation in Downhole Drilling MotorTo keep up with increasing demands for quicker, safer but cost efficient technologies; down hole solutions have been consistently striving towards innovation. Recent Advances in Downhole Drilling Motor Technology Some of the recent innovations n downhole drilling motors include:- Development high-performance elastomers, coatings and seals to improve durability and reliability fdownale polling motoa Integration at sensors end telemetry devices to measure enA hn,smit real time data on too hole conditions i.e. Temperature pressure r6ration-snd torque; - Use D advanced drilling fluid systems na software 10 optimize perfor- moree ef dome trill g retore AnO reduce environmental impact 1-Use a permanent magnet or electric sodding ma tors increase power And e ciency uni Scene fewer nerlodic man tenanclIFImpact! Downhole Drilling Motor and SecuritySafety is always on the top of every drilling operation, including using a downhole drilling motor. When we use a downhole drilling motor, it is necessary to comply with the appropriate procedures and standards used in either prevent accidents or decrease equipment failure. Downhole drilling motor safety precautions:-Regular inspection and proper maintenance of the equipment, including drill-string, supporting components.-Appropriate selection and handling of any used fluids to avoid corrosion or wear on the motor-Effective team coordination among engineers operators and members in charge with details concerning variables during well-drilling procedure for performance monitoring as well as respond promptly regarding issues arise-Protection from Flash fire triggered by H2S use appropriate personal protective accessories -Use Head Protection eye protection prescription PPE gloves when exposed hazardous chemicals while operating this kind machine It is important that all workers will be aware current regulations set forth OSHA so everyone stays safe their job usage these devices Workers do enjoy working carefully over anyone who travels unattended down hole without taking preventive measures. Quality and services of Downile drilling motorWhen selecting a downhole drillingmotor, the quality is important part as well but together with its manufacturer service. Rigorous testing and quality control to guarantee the performance and reliability of downhole drilling motorOn-site technical support for installation, operation & troubleshootingWarranty and repair services so as to prevent downtime in case of any defects or damageCustomisation & engineering service in order to tailor a specific solution designed specifically for your drilling conditions/systems based on each application requirements. Downhole Drilling Motor ApplicationsAlthough the type of formation, wellbore design and drilling objectives provide some control over which specific down hole motor is used w or more HP's are needed for heavy applications, here are a few example scenarios where different motors would each be best suited: A few of the common applications for downhole drilling motor comprise:- Directional Drilling, to attain plural objectives or steer clear of geologic or construction barrears- Underbalanced Drilling: To skirt constituents impairment and raise efficiency - Re-entry Drills: Recycling earlier drilled land holes in addition stretching well run - Geothermal systematic investigation drilling meant for capturing natural warmth from planetoid plus making breastplate merit vitality production Mining Extractor Drill hole begins this blue earth endow with worktable opulence minerals_actions next part ores under underneath. Top 5 Manufacturers for Downhole Drilling Motor in Brazil1 Based on the above criteria, here are top 5 manufacturers:Downhole drilling motorLogo Manufacturer NameHeadquartersAcumen Research and Consulting IndiaThis entry was posted in Energy & Power. Baker Hughes - Baker Hughes is a key provider of oilfield services globally, delivering drilling and evaluation products and services including downhole drilling motors. With more than a 100 years in experience The company being known for its infrastructure capabilities, Baker Hughes also offers World class innovative technologies such as the industry-leading AutoTrak Curve Rotary Steerable System which merges both Azimuthal deflection and telemetry. 2. 8-HalliburtonHalliburton is a global oilfield services company with activities in Brazil as well. Its range of downhole drilling motors includes the high powered Quad-D directional drilling motor for difficult and demanding conditions. 3. National Oilwell VarcoNOV is one of the largest manufacturers drilling equipment and technology in oil & gas, they manufacture downhole drilling motors. Its Black Viper motor is built for higher torque and rotating speed, with the Cervus motor being modular so that disassembling it is a breeze if repairs are necessary. 4. Schlumberger Schlumberger is a global oilfield services company which provides an array of solutions for drilling, reservoir characterization and production sector, among them downhole drilling motors. It is powered by the company's PowerDrive Xceed motor with high-power output, speed capacity and durability, while its EcoScope measurement-while-drilling technology offers real-time measurements of drilling parameters. 5. Weatherford Weatherford is an international oil and gas services company with a specialization in downhole drilling motors. In high-cost environments, the Magnusultra ROTH rotary steerable system provides responsive wellbore geometry control and delivers significant value to operators. Similarly, its RipTide drilling motor offers superior reliability in harsh conditions for consistent performance with minimal maintenance expense. ConclusionSelecting the right downhole drilling motor in Brazil might seem like a slightly daunting job, however if you take into account our factor of benefits vs all other criteria as well as examine into the products for up 5 manufacturers that produces it they will make an informed decision and what better fits your brazilian bit design The Highest Drillmec Provider You Can Trust Today When you work with a trustworthy manufacturer, your drilling operations will be more accurate and efficient while improving productivity, speeding up cycle times at reduced labour costs which add to the success of your industry.